Project Update Bulletin 18

/During September, a special type of protective metal-welded cladding was fitted to parts of the inside of the boiler to prevent erosion by the flue gases during operation.

The next stage is to install a refractory lining to the hottest parts of the boiler to protect the furnace shell, in the lower part of the boiler where the waste is incinerated, from the high temperatures it will endure.

External insulation of the boiler equipment in the basement (including the heat exchanger and air ducts to preheat the air going into the boiler) is almost complete and work has started on installing the insulation below the boiler’s super heaters. The insulation will retain the heat within the boiler, which in turn increases the facility’s energy efficiency.

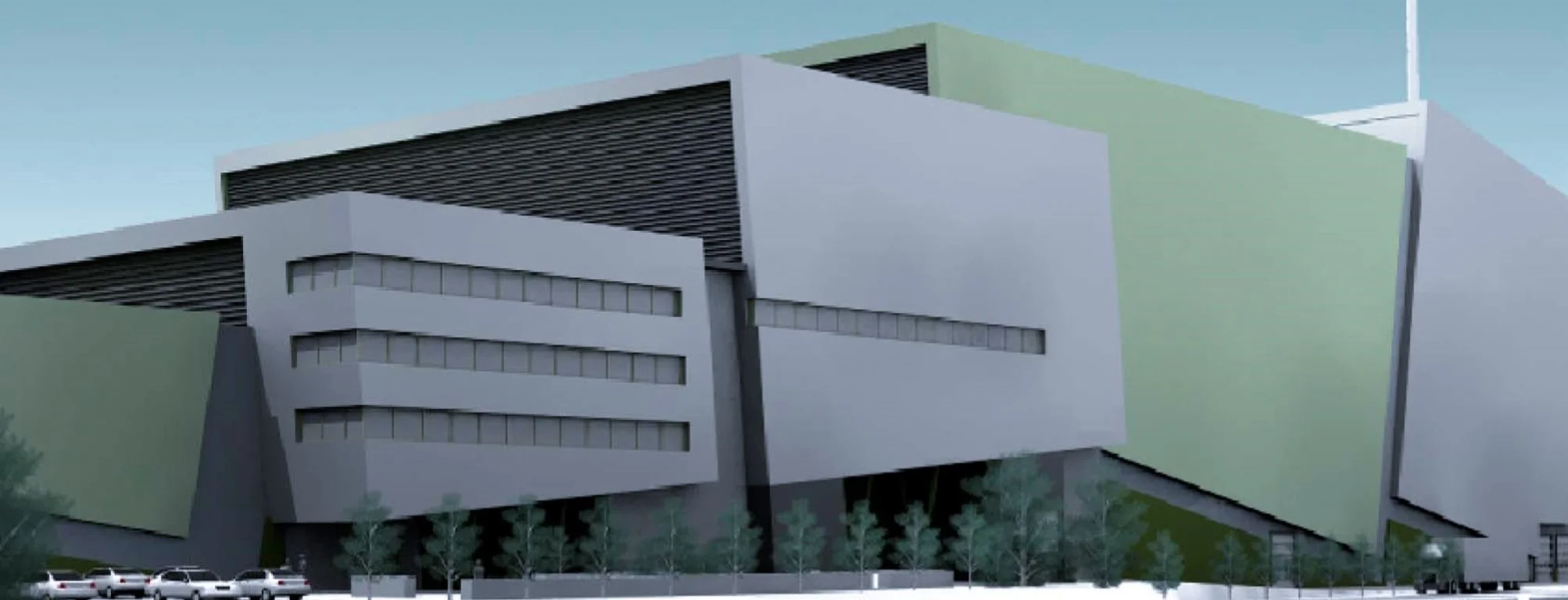

The steel structures that support the building are almost finished and ready for the external cladding to be completed during November and December. Western Power Distribution’s 33kVa power cable has been installed and the facility is now ‘energised’ which allows power to be used to start cold commissioning, and also will allow electricity to be exported to the grid once fully operational. Installation of the pipework connecting the boiler, turbine, and other process equipment within the facility is progressing to schedule. The first system hydrotests, which check the piping for strength and leaks, are currently taking place.

The final electrical cables and pipe work are being installed in the flue gas treatment hall. The flue gas treatment equipment will clean the boiler gases before they are released into the atmosphere, and is scheduled for completion in December.

The electrical equipment, which controls the operation and gathers control signal information in the facility, is currently being installed in the electrical rooms, boiler hall and other process areas. The Air Cooled Condenser, which condenses residual steam back into water to be reused by the facility, is currently under construction at the south end of the boiler hall.

The ash handling equipment, conveyors, and incinerator bottom ash treatment systems have also been installed in October and the final civil elements of the facility are nearing completion. This includes work on the fire water tank which is being covered with soil, and the construction of external ponds and drainage works, which will retain excess water and manage the rain water across the site.

The Gloucestershire Energy from Waste facility is part of Gloucestershire’s Joint Municipal Waste Management Strategy, which aims to reduce, recycle, and recover waste materials across the county, and move away from reliance on end-of-life landfill.

For more information about the project, please visit www.ubbgloucestershire.co.uk. Our emergency out-of-hours contact telephone number is 07860 268578.