Project Update: We are Energised

/During November, activities have continued to increase as construction enters its final stages. The boiler has been fitted with refractory lining to protect the furnace shell from the high temperatures of the grate, and external insulation has been fitted to its superheaters - these increase steam temperature and, in turn, the facility’s energy efficiency.

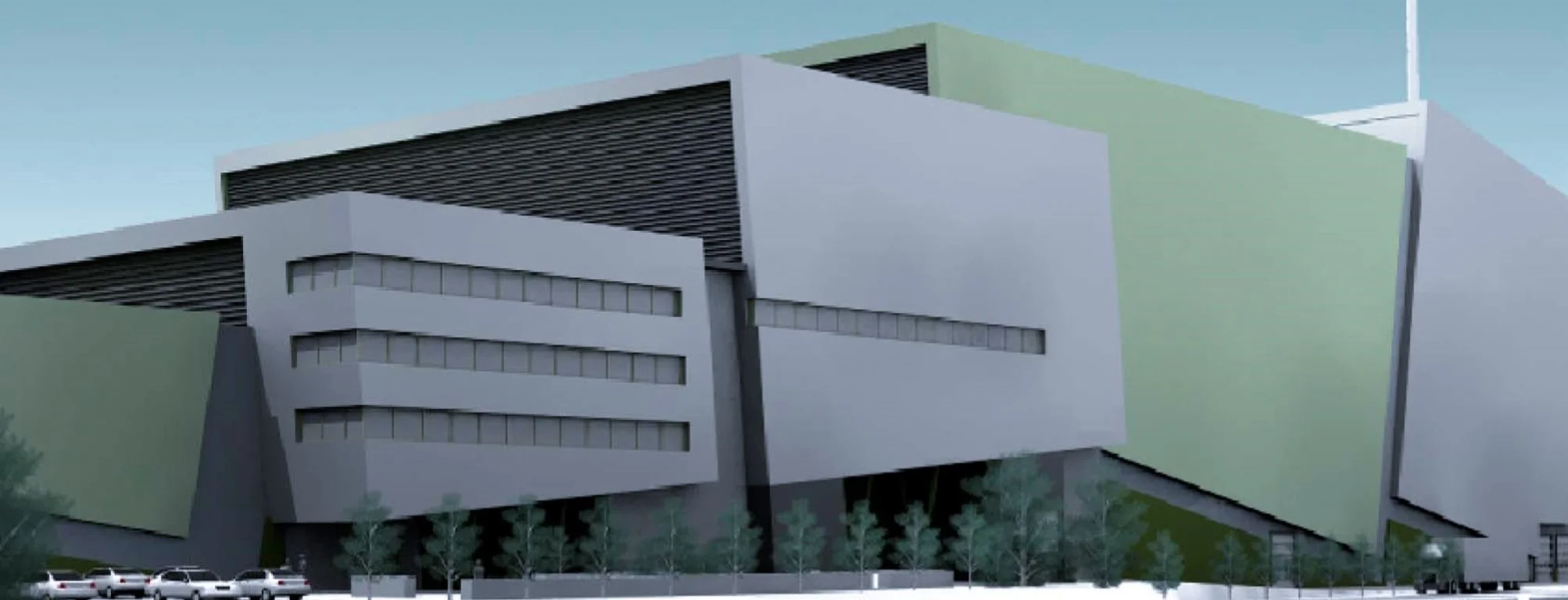

The building’s steel structures are almost complete, allowing the final elements of the external facade to be installed. Pipework connecting the boiler, turbine, and other process equipment within the facility is being installed, with the first system hydrotests, which check the piping for strength, taking place through December.

The ash handling equipment, such as conveyors and incinerator bottom ash treatment systems are now under final installation, and live tests of these conveyors are planned to begin this month. The final civil elements of the facility including the building of on-site car parks are almost complete.

With the facility now energised, cold commissioning is ready to begin in December. Urbaser Balfour Beatty (UBB) has energised the low voltage main switchboard, which provides energy to all electrical power systems on site. The Uninterrupted Power Supply (UPS), a critical component of any facility, which provides power in case of an electrical fault or other emergency shutdown, has also been connected to the National Grid.

Electrical equipment to control energisation, and gather information used by operators to control systems in the facility, is currently being installed in the electrical rooms, boiler hall, and other process areas. The Air Cooled Condenser, which condenses residual steam back into water to be reused by the facility, is under construction at the south end of the boiler hall. The Distributed Control System (DCS), the ‘brain’ of the facility that gathers data from the control systems, has been tested prior to connection and final site testing. Once completed, this will allow for the functional testing of the equipment interfaces at the facility.

System tests will run for two to three months to verify the functioning of all elements of the facility. The tests will confirm that measurements from the equipment are correctly recorded and all safety systems are working properly. Once these functional tests are performed, sequence tests will be run to verify that all equipment is running in the correct order via the DCS. Once all tests are completed, hot commissioning will begin.