Project Update Bulletin 16

/There has been a lot of activity to install the boiler, including operatives and welders working in two shifts to progress the works.

All of their hard work means that the boiler pressure test is set to take place as on schedule this month. Boiler pressure testing is a construction milestone, and a regulatory requirement in the construction of Energy from Waste facilities.

The test demonstrates the build integrity of the boiler, and is just one of a number of assurance measures used to ensure the materials and workmanship are of the highest quality. The test is quiet and will not cause any disruption to traffic, pedestrians or local residents. During the test, the boiler is filled with water and pressurised to demonstrate that it is able to achieve the operating pressure requirements specified within the design.

The test is in two parts: the first part is a visual inspection which is expected to take approximately six hours, followed by the second element, the pressure retaining test, which takes 30 minutes to complete depending on specific design code parameters.

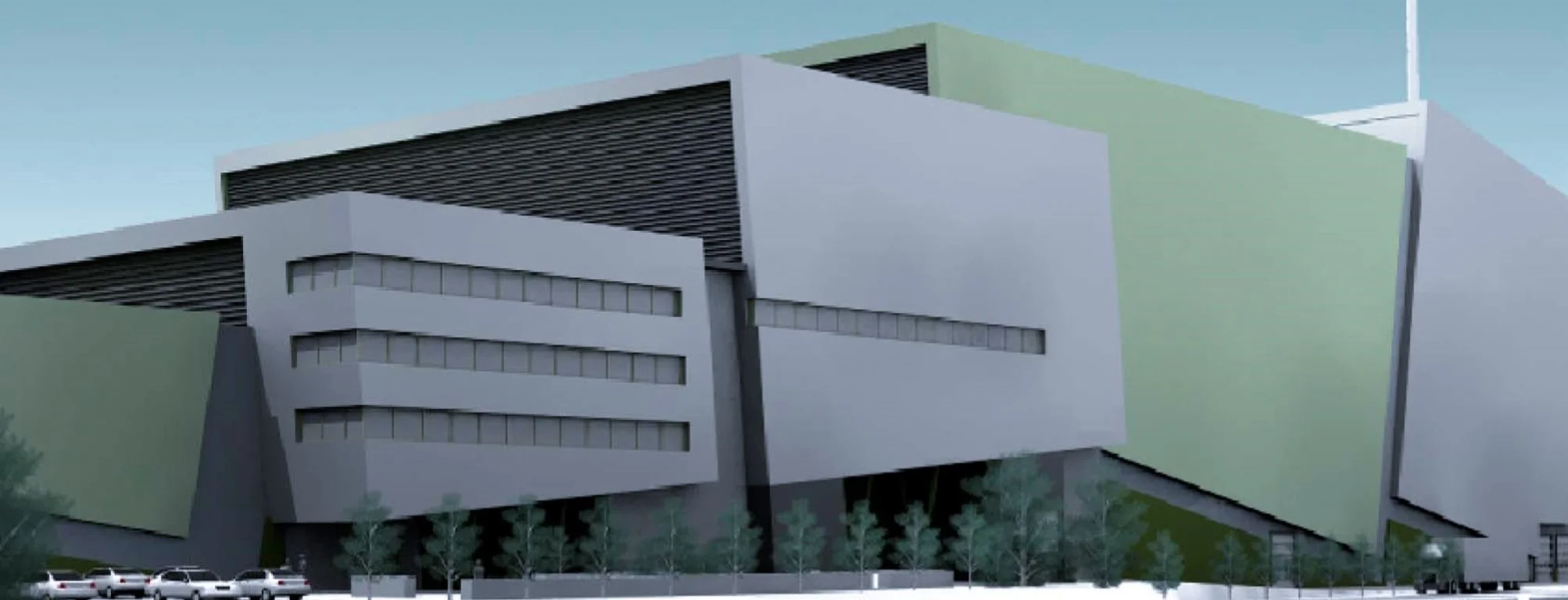

A number of other activities continue on site, including the construction of steel structures to support the buildings, which we expect to complete over the summer. Installation of the 33kV Western Power Distribution (WPD) electrical equipment that connects the facility to the National Grid is now complete and ready for testing before energisation.

These works allow WPD to bring power to the site and ultimately allow power to be exported from the site back to the National Grid during commissioning and operation, and then into homes and offices. The flue gas treatment equipment has been installed, with installation of the piping and electrics starting in the coming weeks. UBB have already begun the installation of electrical panels including the step up and auxiliaries transformers.

The step up transformer allows the power generated on site to be increased from 11kv (3 phase) to 33 kv before being exported from the site to the grid. The auxiliary transformers allow the power on site to be distributed throughout the site for general power consumption during the operation of the plant.

The incinerator bottom ash (IBA) conveyor equipment in the boiler area, which will transport the IBA from the boiler to the storage area, is complete, and we are currently installing the conveyor system in the IBA hall.

Urbaser Balfour Beatty have also produced a short reportage film about the construction progress on the site. Now past the halfway point, construction at the facility is progressing at a fast rate, and the report provides insight into the work currently taking place on site, and the key benefits of the site once operational.

For full information, watch the full four-minute video here: https://www.ubbgloucestershire.co.uk/news/2018/7/14/ubb-gloucestershireconstruction-progress-film-july-2018

For more information about the project, please visit www.ubbgloucestershire.co.uk. Our emergency out-of-hours contact telephone number is 07860 268578.