Project Update: A hive of activity

/All elements of the construction and process equipment installation are progressing at a fast rate, and almost all of the structural steel supporting the process equipment is now in place. A key element in this part of the programme is the instalment of the steel frame over the waste storage bunker, which will support the bunker building as well as the cranes that will load waste into the combustion grate feed hopper.

The last major structural element of the facility is the framework to support the Air Cooled Condensers (ACC), which will start shortly. After its passage through the turbine, the steam that has provided energy for power generation will then pass through the condensers and is turned back into water to be recirculated and reused in the boiler.

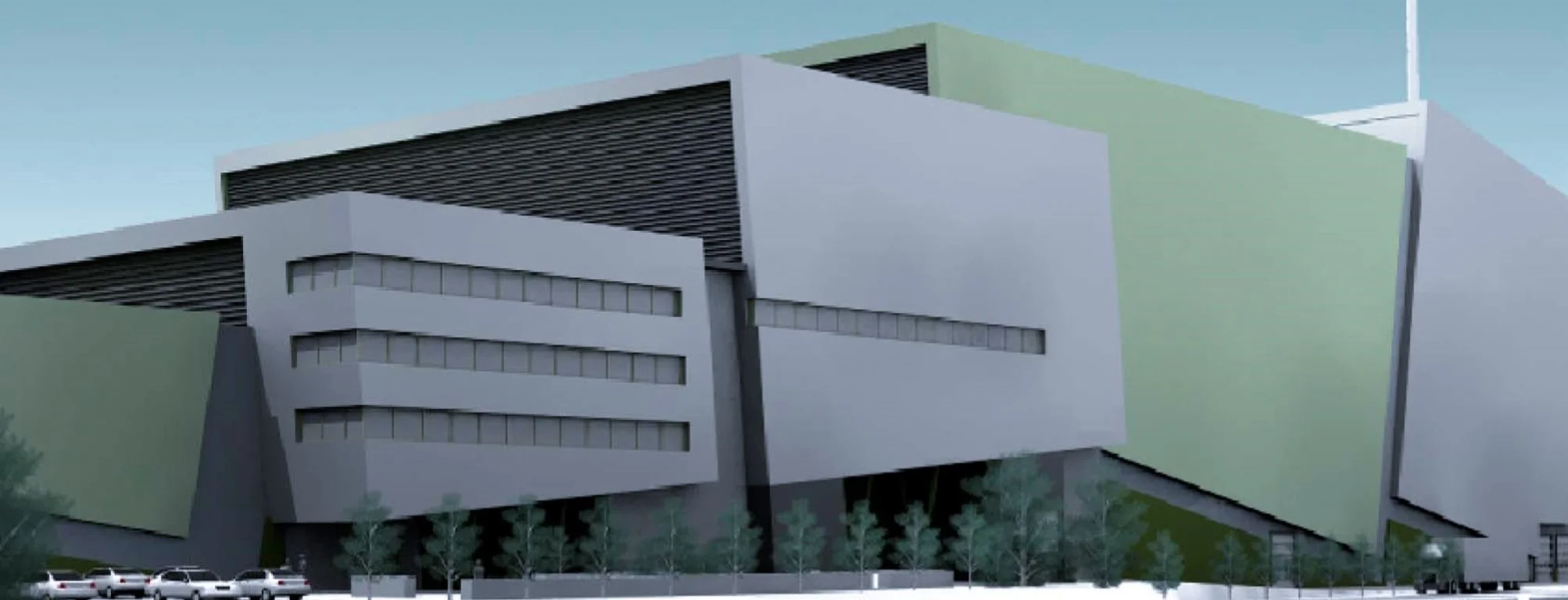

The main buildings are now taking shape, with the roof and cladding of the incinerator bottom ash hall nearing completion, and cladding of the administration block now in progress. The construction of the concrete fire water storage tank, which is located between the site entrance and the main buildings, will be completed during the summer. Once constructed, the tank will be covered and surrounded by a soil mound, which will be landscaped under the approved scheme.

The main elements of the flue gas treatment system have been installed and are now being connected together. The system is made up of the gas cooling tower, the treatment vessel (where lime and activated carbon are injected into the gas stream to capture potentially harmful substances and reduce acidity), and the bag filters to collect the gas treatment products. The main fan and associated pipework, which will draw the cleaned flue gases through the treatment system and up the stack, are also in place. The storage silos for the lime and carbon used in flue gas treatment, and the silo to hold the spent lime products after gas treatment are now in position close to the stack.

The steam turbine, gearbox, and electricity generator are now installed at ground level in the turbine hall adjacent to the grate. Elements of the electricity transformer (which will step up the generated power from 11kV to 33kV), and the substation, have arrived on site and are being installed.